Deliver to

Ship from Local Warehouse

Ship from Local Warehouse

Shipped By:

Security & Privacy

Security & Privacy

FREE Return

FREE Return

BB Spotting Drills-60,90,120 degree drill point.TiN coated HSS:-For mild steel and other soft metals.-Manual grinding.-It's not only as a center …

BB Spotting Drills

-60,90,120 degree drill point.

TiN coated HSS:

-For mild steel and other soft metals.

-Manual grinding.

-It's not only as a center drill but as a chamfer tool as well .

-For accurate spotting on Machines.

-Precise drill positioning.

-Short lengths and no body clearance make this a very rigid tool.

In order to reduce factors that are not good for machining, such as uneven part surfaces or slightly used drill bits, a simple way to avoid "slipping" is to use a fixed-point drill. The tool is designed to leave a dent on the surface of the part so that the drill bit can be engaged during the drilling process and maintain its correct alignment to prevent the drill bit from deviating from the route.

Geometry

The shape of the spot drill is short and thick, the chip removal groove is very short, and the alloy centering drill with excellent rigidity has better effect. Its drill tip geometry is just enough to drill a shallow hole on the surface of the workpiece; Compared with standard drills, the centering drill has a very thin chisel edge, which can effectively cut the workpiece material.

Dimensions

-Long Length of HSS:

d3*100L

d4*120L

d5*120L

d6~16*150L

-Long Length of carbide:

100mm

4PCS :3mm 4mm 5mm 6mm

5PCS :3mm 4mm 5mm 6mm 8mm

6PCS :3mm 4mm 5mm 6mm 8mm 10mm

7PCS :3mm 4mm 5mm 6mm 8mm 10mm 12mm

Machining parameter

HSS:

RPM:150~1100 Feed:0.06~0.2

Carbide:

RPM:650~2500 Feed:0.08~0.2

Whether the cutting speed and feed rate are appropriate depends on the workpiece material, the insert substrate and the coating, as well as the requirements of the drilling process itself.

In general, the cutting speed and feed rate of centering drilling should be lower than that of secondary drilling. The purpose of centering drilling is only to provide a correct starting hole position for secondary drilling, so it is not necessary to achieve a high drilling rate.

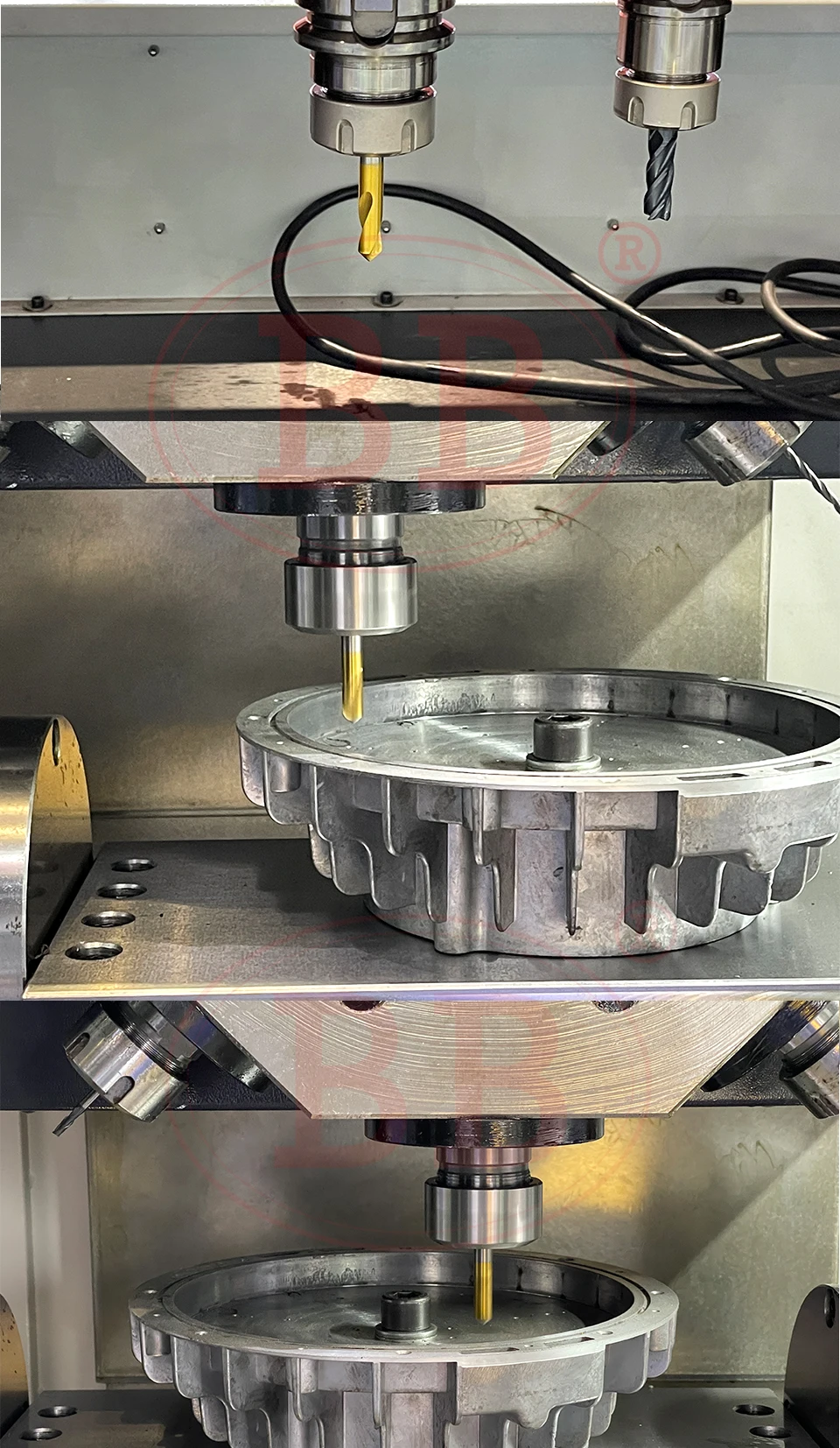

Testing

Drilling

Before the drilling process, first use a spot drill to drill hole with a depth of 1 to 2 times the diameter to ensure the accuracy of the drilling process of ordinary drill bits, and reserve chamfers for tapping to facilitate tapping.

The drill tip angle of the centring bit shall be equal to or greater than the drill tip angle of the secondary bit. This can eliminate excessive cutting pressure on the cutting edge of the drill (this pressure will cause the tool to fail in advance and reduce the quality of the hole).

When both the centering drill and the drill bit use the same drill tip angle, the drill tip and cutting edge of the secondary drill bit will cut into the workpiece at the same time. This may cause flutter due to the same cut-in angle, which may cause secondary bit chipping.

For carbide drill bits, it is correct that the tip angle of the fixed point drill should be greater than the tip angle of the secondary drill bit. However, for high-speed steel secondary drills, we hope that the cutting edge can cut into the workpiece before the drill tip. Because the cutting edge of the high-speed steel drill bit is not as fragile as the carbide drill bit, we hope that the cutting edge will contact the workpiece before the chisel edge, and the drill tip will not participate in the cutting.

Carbide drill is just the opposite. Cemented carbide drill bits are usually designed to reduce the chisel edge. Due to the brittleness of cemented carbide, we do not want the cutting edge to cut into the workpiece first. Therefore, it is recommended to use a centering drill with a larger drill tip angle, so that the chisel edge can be cut into the workpiece before the cutting edge.

When is it not recommended?

When an irregular surface is being machined, such as the side or inclined plane of a cylinder, this point drilling may not be enough to hold the hole in the correct position. In these cases, a flat-bottom drill may be more appropriate.

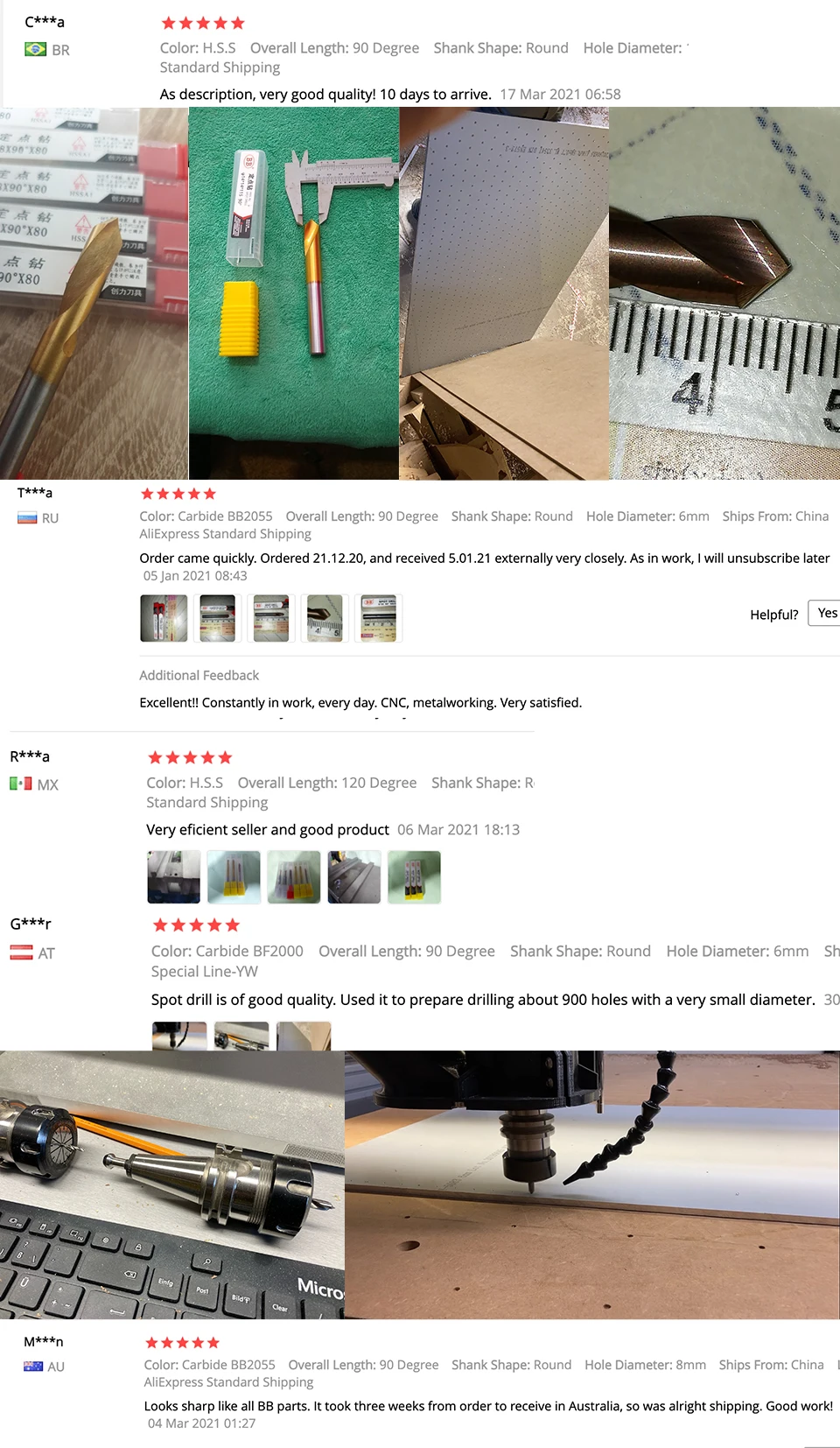

Customer Reviews

HI, welcome to BB official store.

-We are professional manufacturer ,development and production of milling tools.

-We provide various tools for you . You can follow us and see more.

-You have free choice of collocation, pick different specifications and other tools in our store to you cart and pay them together. We will send the products you have picked as a package.

-Take an additional 5~10% off when you buy 10 pieces or more.

SHIPMENT

-We have already paid 50% of delivery cost when you choose AliExpress Standard Shipping.And free shipping for sometimes.

-Orders processed timely after the payment verification.We ship products within 3 working days.

-The trade is cross-border, and Airmail is cheapest post which take a long time for delivery.If you need the item urgently ,please choose Express way.

-If you have not received your shipment within 60 days from payment, please contact us. We will track the shipment and get a reply to you as soon as possible.

We sincerely hope that BB tools will meet your full requirements. Please enjoy your online shopping.