Toocki Direct Store

Deliver to

Columbus Free Shipping

Delivery bySaturday, April 12, Limited Time Offer

Free Shipping

Delivery bySaturday, April 12, Limited Time Offer

Ship By: EZARC Global Store

Fast Delivery

Fast Delivery

Security & Privacy

Security & Privacy

FREE Return

FREE Return

EZARC Step Drill Bit for Metal, M35 Cobalt Step Drill Spiral Flute Unibit Step Drill Bit (4-20mm) Wear-Resistant AlTiN Coated, 1/4" Hex Shank for…

【9 Step Sizes】Spiral flute design, featuring 9 distinct steps from 4 to 20 mm, offers seamless and effective drilling across various thicknesses, eliminating the need for multiple bits. Includes 4 mm, 6 mm, 8 mm, 10 mm, 12 mm, 14 mm, 16 mm, 18 mm, 20 mm.

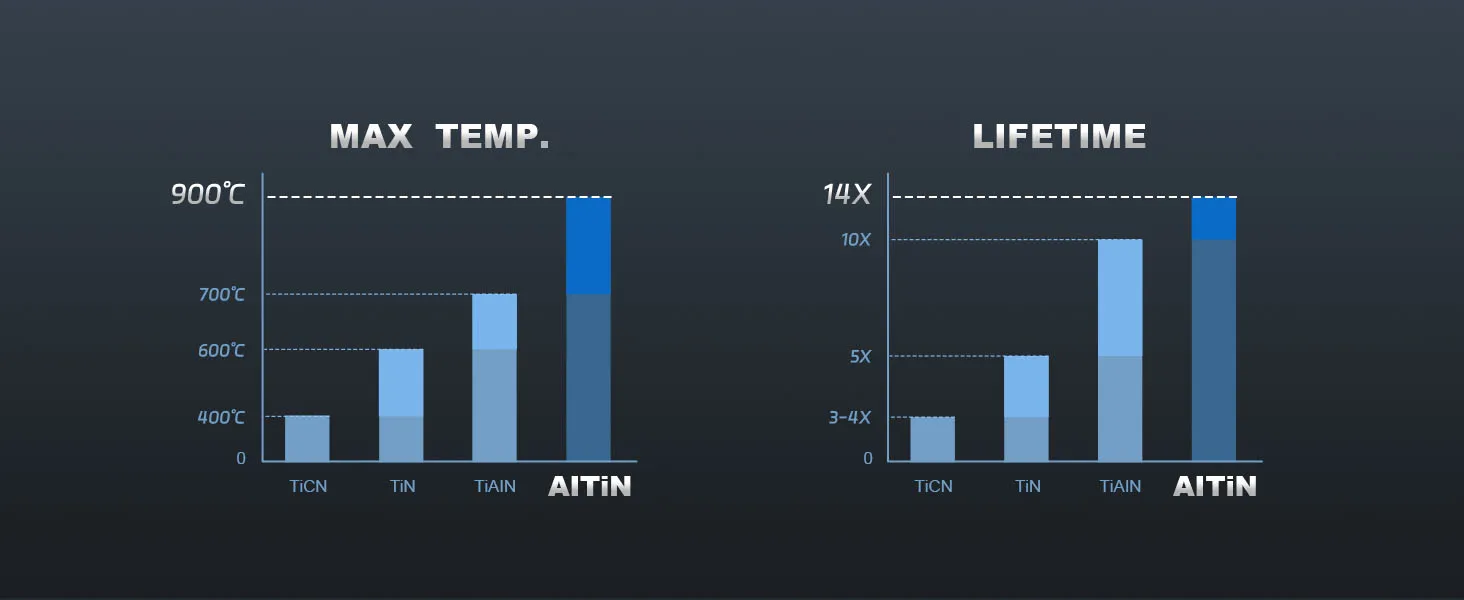

【AlTiN Coating】Step bits coated with aluminum titanium nitride, rated at 89HRC for exceptional hardness and thermal properties. This coating offers superior resistance to heat, wear, and corrosion, with high adhesion and low friction. Laboratory tests show it more durable than steamed black oxide coating for longer bit life.

【C-Profile Design】EZARC Step Drill Bits feature a triple-flute design for enhanced stability, effectively addressing issues of deviation during the cutting process. Additionally, 'C-profile' cutting edge ensure smoother cutting and 2X increase in cutting speed.

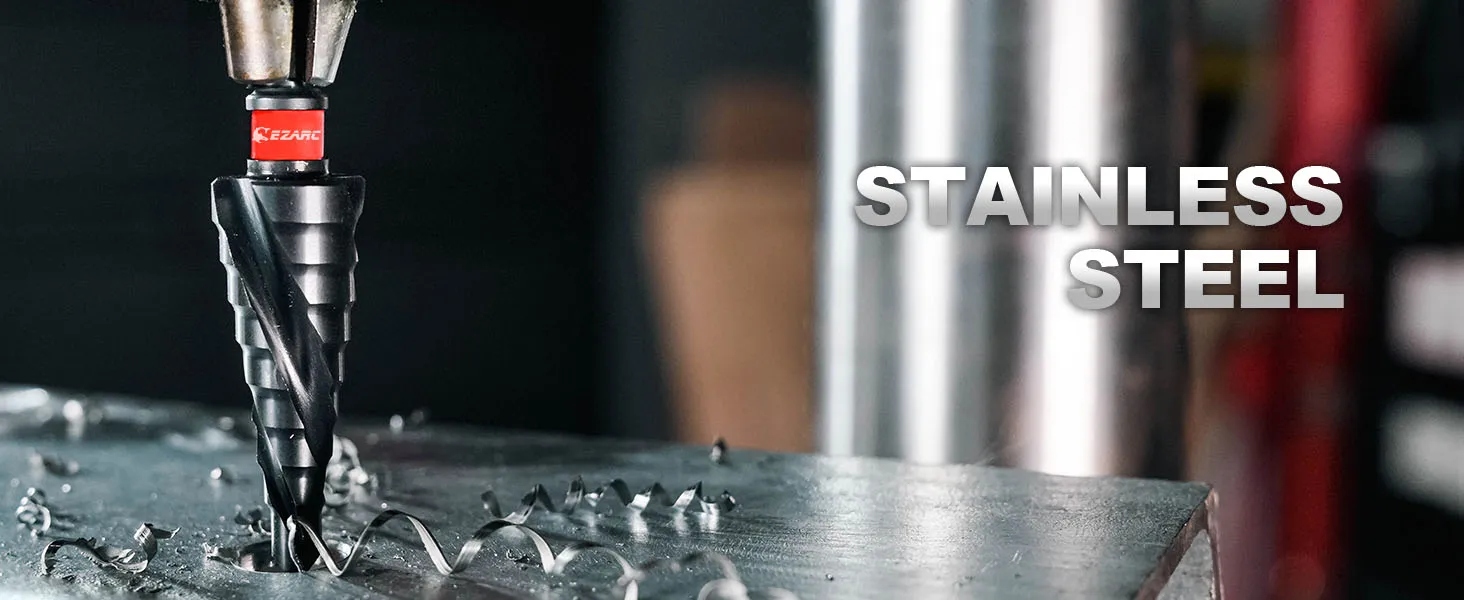

【M35 HSS Step Drill】M35 cobalt high-speed steel achieves high levels of hardness and wear resistance through appropriate heat treatment. Its toughness and bending strength surpass those of standard high-speed steel, making this step drill bit more suitable for cutting harder materials, such as mild steel, medium hardness steel, stainless steel.

【Please Note】Follow these tips to keep your drill in top condition: add cutting oil or spray water to cool during continuous use, the start-up speed will be slower due to the larger cutting angle, any quality problems, please feel free to contact us.

1.How will AlTiN coating affect the performance of step drills?

AlTiN Coating, with a hardness of 89 HRC, offers excellent hardness and thermal properties. It provides great resistance to heat, wear, corrosion and can withstand temperatures up to 900°C.

2.What types of metal can I cut with ezarc step drill bit?

You can use EZARC step drills to cut or drill through various metals, including aluminum, brass, copper, cast iron, galvanized pipe, stainless steel, and low-carbon steel.

3.How do I properly use this step drill bit?

Ensure the chuck is securely tightened on the power tool. Use low speed and apply light pressure on the workpiece until reaching the desired depth. Lubricate the cutting edge with oil or a water-soluble lubricant to reduce friction, heat, and debris.

4.Are there any requirements for the thickness of the materials used?

The thickness of metal plates should not exceed 3mm, and the thickness of stainless steel plates should not exceed 1mm.